Related Products

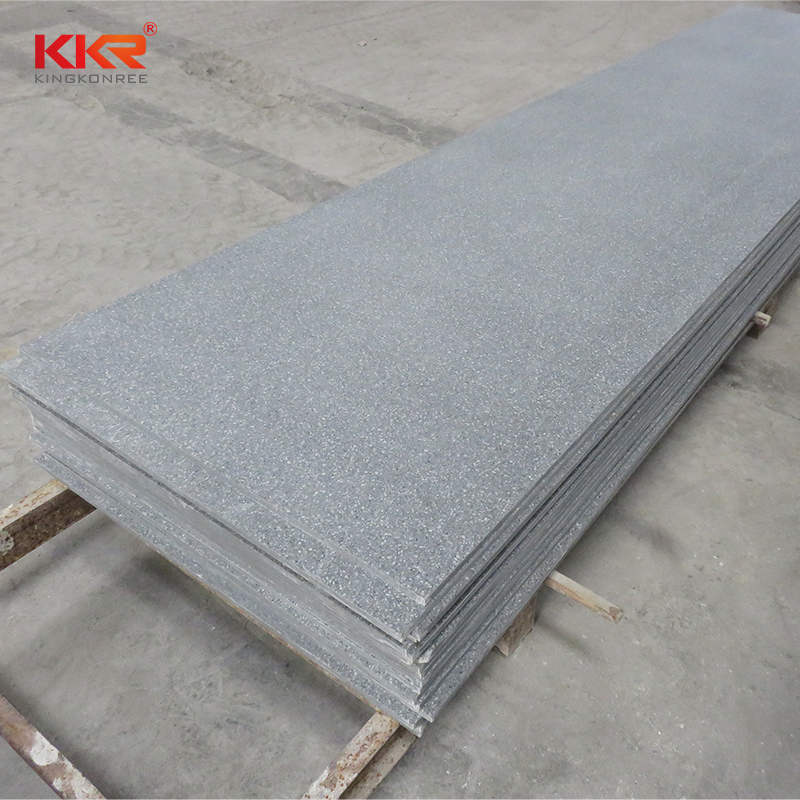

| Model No | KKR-M2715 |

|---|---|

| Colors | More than 300 colors for choice, color customization available also according to your samples |

| Warranty | 10 years |

| MOQ | 30pcs/color |

| Certificate | CE & SGS & UL |

| Package | Foam + PE film + nylon strap + E0 standard plywood box |

| Delivery Time | 15--20 working days for 20 ft container |

| Payment terms | T/T or western union, 50% in advance as deposit, and 50% balance paid before delivery. |

Copyright © 2019 Huizhou KKR Stone Industry Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.