Welcome to the fascinating world of solid surface! If you're looking for a versatile and durable material that can elevate the aesthetics of your space, while also offering practicality and ease of maintenance, then you've come to the right place. In this blog post, we'll delve into everything you need to know about solid surface – from its composition and manufacturing process, to its properties and advantages over other materials. Whether you're an interior designer, homeowner or business owner, understanding the many benefits and applications of solid surface will surely inspire your next project. So let's dive in and explore this remarkable material together!

What is Solid Surface?

Solid surface is a remarkable material that has gained immense popularity in the world of interior design and architecture. But what exactly is solid surface? In simple terms, solid surface refers to a type of synthetic material commonly used for countertops, sinks, and other surfaces in both residential and commercial settings.

▪ Composition and Manufacturing Process

The composition and manufacturing process of solid surface is a fascinating blend of science and artistry. It starts with carefully selected ingredients and components that are mixed and blended to create a homogeneous mixture. These components include minerals, pigments, acrylic resins, and other additives. In the mixing stage, the components are combined in precise ratios to ensure consistency and quality. This mixture is then poured into molds or shaped using specialized techniques such as vacuum forming or thermoforming. The material is heated to cure it, resulting in a solid surface sheet with uniform thickness.

One of the key advantages of the manufacturing process is its ability to produce seamless sheets without any visible joints or seams. This makes it ideal for creating large surfaces like countertops or wall cladding where aesthetics are important. The properties and characteristics of solid surface also make it highly durable and resistant to stains, scratches, heat, and moisture. Its non-porous nature prevents bacteria growth making it hygienic for use in healthcare settings.

The composition and manufacturing process behind solid surface ensures that it meets high standards of quality while offering design flexibility, durability,and easy maintenance for various applications in both residentialand commercial spaces.

One major advantage of solid surface is its non-porous nature, which means it doesn't absorb liquids or harbor bacteria like traditional materials do. It's also resistant to stains, heat damage, scratches, and UV rays. Additionally, solid surface can be seamlessly joined together without any visible seams.

Solid surface is a versatile and popular material used in various applications, including countertops, furniture, and wall cladding. Understanding its composition and manufacturing process can help us appreciate its qualities and advantages. The ingredients of solid surface typically include a blend of acrylic or polyester resins, minerals such as aluminum trihydrate (ATH) or calcium carbonate, pigments for coloration, and additives for enhanced performance. These components are carefully selected to achieve the desired properties of the final product.

The mixing and blending process is a crucial step in the manufacturing of solid surface materials. It involves combining various ingredients to create a homogenous mixture that will later be molded and shaped into desired forms. To begin, the ingredients for solid surface sheets are carefully measured and weighed according to specific formulations. These formulations can vary depending on the desired properties of the final product, such as color, texture, and durability. Once the ingredients are ready, they are mixed together using specialized equipment. The mixing process ensures that all components are evenly distributed throughout the mixture, resulting in a consistent material with uniform characteristics.

Blending is another important part of this process. It involves thoroughly combining different colored or patterned materials to create unique designs or effects within the solid surface sheets. This allows for endless possibilities when it comes to creating custom countertops or furniture pieces. The mixing and blending process plays a vital role in achieving high-quality solid surface products. By carefully controlling ingredient ratios and ensuring thorough blending, manufacturers can produce durable and visually appealing materials that meet customer specifications.

Molding and shaping techniques play a crucial role in the manufacturing process of solid surface materials. These techniques allow for the creation of unique and intricate designs that can enhance any space. One common technique used is thermoforming, where the solid surface sheets are heated to a specific temperature, making them flexible and easy to mold. This allows for seamless curves and bends to be created, resulting in stunning countertops or furniture pieces.

Another technique is CNC machining, which involves using computer-controlled machines to precisely cut and shape the solid surface material. This method provides endless possibilities for customization, whether it's creating intricate patterns or adding decorative details. In addition to these techniques, there are also options for hand sculpting or carving the solid surface material. Skilled artisans can create one-of-a-kind pieces with intricate detailing that truly showcase the versatility of this material. Molding and shaping techniques give solid surface materials their distinctive look and feel. Whether you're looking for sleek modern designs or more traditional styles, these techniques ensure that your solid surface creations will be both visually appealing and functional.

✔ Design Flexibility and Aesthetic Appeal

Design flexibility is one of the key advantages of solid surface materials, making them a popular choice for both residential and commercial applications. With solid surface, the design possibilities are virtually endless! It can be molded and shaped into any desired form, allowing for unique and customized designs that are tailored to individual preferences.

One of the main reasons why solid surface is so versatile is its ability to seamlessly integrate with other materials. Whether it's combining different colors and patterns or incorporating decorative elements like inlays or backlighting, solid surface can easily adapt to various design styles. This makes it ideal for creating eye-catching focal points or statement pieces in interior spaces. In addition to its versatility, solid surface also offers a wide range of aesthetic options. From classic neutrals to vibrant hues, there is a vast selection of colors available that can complement any design scheme. Moreover, textures and finishes such as matte or high-gloss add depth and dimension to surfaces, enhancing their visual appeal. Another advantage of using solid surface for design purposes is its ability to create seamless installations. Unlike natural stone or laminate countertops where visible joints may disrupt the overall look, solid surface allows for smooth transitions between sections. This not only enhances the aesthetic appeal but also improves functionality by eliminating areas where dirt and bacteria could accumulate.

✔ Easy Maintenance and Cleaning

Solid surface is incredibly easy to maintain, making it a popular choice for busy households. Its non-porous nature means that it resists stains, making spills easier to clean up. Additionally, scratches can often be buffed out with minimal effort. Maintaining and cleaning solid surface countertops is a breeze, making them a popular choice for both residential and commercial spaces. One of the key advantages of solid surface is its non-porous nature, which means that it does not absorb liquids or harbor bacteria. This makes it incredibly easy to clean and maintain.

To keep your solid surface countertops looking their best, simply wipe them down with a soft cloth or sponge and mild soap or household cleaner. Avoid using abrasive cleaners or scouring pads, as these can damage the surface. For tough stains or dried-on food particles, gently scrub with a non-abrasive nylon brush.

Solid surface is that it is resistant to stains, so spills are easily wiped away without leaving any lasting marks. It also has excellent resistance to scratches and heat, but it's always best to use cutting boards and trivets when working with hot pans or sharp utensils. Regular maintenance involves wiping down your countertops daily to remove any dirt or grime that may have accumulated throughout the day. A quick once-over with warm water and soap should do the trick. With proper care, your solid surface countertops will stay looking beautiful for years to come!

✔ Seamless and Integrated Installations

Another advantage of solid surface is its ability to create seamless installations. With proper installation techniques, joints between pieces are virtually invisible, creating a cohesive look. This makes it ideal for countertops where hygiene is important as there are no cracks or crevices for bacteria to hide. Seamless and integrated installations are one of the key advantages of using solid surface in various applications. Whether it's a kitchen countertop or a bathroom vanity, the ability to create a smooth and continuous surface without visible joints or seams is highly desirable.

With solid surface, the installation process involves bonding individual pieces together using adhesive materials specially designed for this purpose. This allows for seamless integration between different sections, resulting in a visually appealing and cohesive final product. The absence of visible seams not only enhances the aesthetic appeal but also provides functional benefits. Without any gaps or joints, there are no areas for dirt, bacteria, or water to accumulate. This makes cleaning and maintenance much easier compared to materials with visible seams.

Furthermore, seamless installations offer additional design possibilities. Solid surface can be shaped and formed into curved surfaces or intricate shapes that seamlessly blend into their surroundings. This allows for creative freedom in designing unique spaces that perfectly fit specific requirements. Seamless and integrated installations contribute to the overall durability and longevity of solid surface applications while providing an aesthetically pleasing finish that seamlessly integrates into any environment.

✔ Repairability and Renewability

In the event that your solid surface becomes damaged or scratched over time, it can easily be repaired by sanding down the affected area. This ability to renew the appearance of the material prolongs its lifespan and saves you money in replacement costs. Repairability and renewability are two key characteristics that make solid surface a popular choice for countertops and other surfaces. One of the major advantages of solid surface is its ability to be repaired if it gets damaged or scratched. Unlike natural stone or laminate, which may require costly replacements, solid surface can often be easily repaired by sanding or buffing out any imperfections.

In addition to repairability, solid surface also offers the advantage of renewability. Over time, even with proper care and maintenance, surfaces can become worn or outdated. With solid surface, however, you have the option to refresh your space without completely replacing your countertops or surfaces. Solid surface can be refinished to restore its original beauty and luster. The process of refinishing involves sanding down the top layer of the material and then applying a new finish to achieve a like-new appearance. This not only saves you money but also reduces waste by extending the lifespan of your existing surfaces.

Solid surface's repairability and renewability make it a cost-effective and sustainable choice for homeowners and businesses alike. It allows for long-term durability while still providing flexibility in terms of design updates or repairs as needed. So whether you want to fix minor scratches or give your kitchen a fresh new look, solid surface offers an ideal solution that combines functionality with aesthetics.

✔ Environmental Sustainability

Solid surface is an environmentally friendly option due to its durability and longevity. By choosing solid surface products made from recycled materials or opting for renewable energy during manufacturing processes, you are contributing to sustainable practices. Environmental sustainability is a crucial consideration in today's world, and solid surface materials are leading the way in this aspect. One of the main reasons why solid surface is considered environmentally friendly is its composition. It typically consists of natural minerals, acrylic polymers, and other recycled materials.

Moreover, the manufacturing process of solid surface also contributes to its eco-friendliness. The production involves using renewable energy sources and reducing waste through recycling and reusing materials whenever possible. This not only helps in conserving resources but also minimizes the environmental impact. In addition to being made from sustainable materials and manufactured with eco-friendly processes, solid surface is also recyclable at the end of its life cycle. Unlike some other materials that end up in landfills or contribute to pollution when discarded, solid surface can be crushed down into granules and reused for new products. Furthermore, since solid surface countertops are highly durable and long-lasting, they reduce the need for frequent replacements. This means less waste generated over time compared to other countertop options that may wear out sooner.

By understanding the advantages offered by solid surfaces such as design flexibility, easy maintenance&cleaning, and repairability along with their environmental sustainability, you can make an informed decision when selecting materials for your next project!

Comparison vs. Other Matirials

When it comes to choosing the right material for your countertops or furniture, solid surface is a popular option that offers many advantages over other materials. Let's take a closer look at how solid surface compares to some commonly used alternatives.

Solid surface and natural stone are two popular options when it comes to countertops and other surfaces. Each material has its own unique characteristics and benefits, so let's explore the differences between solid surface and natural stone.

In terms of durability, both materials are quite strong. Solid surface is known for its resistance to scratches and stains, making it ideal for high-traffic areas like kitchens. Natural stone, such as granite or marble, also offers durability but may require more maintenance in terms of sealing to protect against stains.

Another important distinction is customization. Solid surface can be easily shaped and molded into various designs due to its synthetic nature. It can even be seamlessly joined together for a sleek look. Natural stone typically comes in slabs with unique patterns that cannot be replicated.

When it comes to maintenance, solid surface wins again with its non-porous nature that prevents bacteria growth and makes cleaning a breeze. Natural stone requires periodic sealing to maintain its beauty and prevent staining. Choosing between solid surface or natural stone will depend on your specific needs and preferences. Both offer their own advantages in terms of design flexibility, durability, and maintenance requirements.

Solid surface vs. laminate: Choosing the right material for your countertop can be a tough decision, especially with so many options available on the market. Two popular choices are solid surface and laminate. Both materials have their own unique qualities and benefits, making it important to understand the differences between them.

When it comes to durability, solid surface takes the lead. Made from a combination of acrylic and natural minerals, solid surface is known for its strength and resistance to scratches and stains. Laminate, on the other hand, is made from layers of paper that are bonded together with resin. While laminate countertops can withstand everyday wear and tear, they are more susceptible to scratches over time.

In terms of aesthetics, both materials offer a wide range of colors and patterns to choose from. However, solid surface has an advantage when it comes to customizability. It can be easily molded into any shape or design you desire, allowing for seamless integration in your kitchen or bathroom.

Maintenance is another factor to consider. Solid surface requires minimal upkeep - just regular cleaning with mild soap and water will keep it looking good as new. Laminate countertops may require more attention as they can be prone to chipping or peeling if not properly cared for. When weighing your options between solid surface vs laminate, take into account factors such as durability, customization possibilities, maintenance requirements,and overall aesthetic appeal that best suits your needs and preferences.

Solid surface and quartz are both popular choices for countertops, but they have their own unique characteristics. Let's take a closer look at how these two materials compare.

One key difference between solid surface and quartz is the composition. Solid surface is made from a blend of acrylic or polyester resins with mineral fillers, giving it a smooth and non-porous finish. On the other hand, quartz countertops are engineered using natural quartz crystals mixed with resin binders.

In terms of durability, both solid surface and quartz are known for their strength. However, quartz tends to be slightly harder than solid surface, making it more resistant to scratches and chips. Solid surface countertops can be repaired if damaged, while repairs on quartz may require professional assistance.

When it comes to maintenance, solid surface is easier to clean as it does not require sealing or special cleaning products like some other materials do. Quartz also offers low-maintenance benefits but may need occasional resealing depending on the manufacturer's recommendations.

Design-wise, both materials offer a variety of colors and patterns to choose from. However, since quartz contains natural minerals that give it its distinctive appearance, it can mimic the look of natural stone more accurately than solid surface. Whether you choose solid surface or quartz will depend on your personal preferences in terms of aesthetics, durability needs, and budget constraints. It's always best to consult with professionals who specialize in countertop installations before making your final decision.

When it comes to choosing the right material for your kitchen or bathroom countertops, there are many options available in the market. Among these, solid surface and acrylic are two popular choices that offer durability and aesthetic appeal. While they may seem similar at first glance, there are some key differences between the two.

One major difference is in their composition. Solid surface is made from a blend of natural minerals and resins, while acrylic is a synthetic material derived from polymers. This distinction affects the overall performance and characteristics of each material.

In terms of durability, both solid surface and acrylic are known for their strength and resistance to impact. However, solid surface tends to be more resistant to scratches than acrylic surfaces.

Another important aspect to consider is maintenance. Solid surface requires minimal upkeep; it can be easily cleaned with soap and water without worrying about damaging the surface. On the other hand, acrylic surfaces require regular polishing as they tend to show scratches more prominently.

Design flexibility is another area where these materials differ. Solid surface offers a wide range of colors and patterns that can mimic natural stone or create unique designs. Acrylic also offers design versatility but has limitations when it comes to replicating natural textures. When it comes down to cost, both materials fall within a similar price range; however, solid surface tends to be slightly more expensive due to its superior quality and durability. Choosing between solid surface and acrylic depends on your specific needs and preferences. Whether you prioritize ease of maintenance or desire unlimited design possibilities will influence your decision-making process.

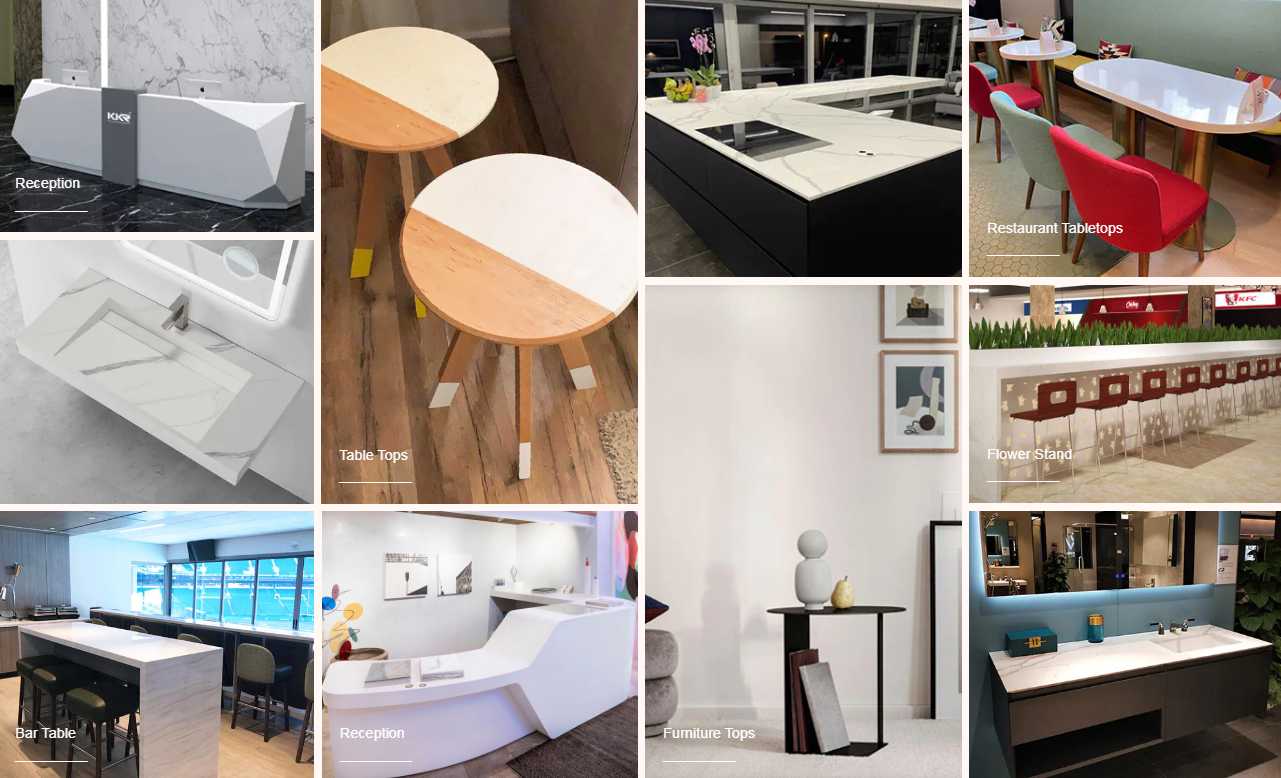

Solid surface materials have a wide range of applications due to their versatile nature and durability.

▪ Kitchen and Bathroom Countertops

One common use for solid surface is in kitchen and bathroom countertops. Their non-porous nature makes them resistant to stains and bacteria, making them ideal for these high-traffic areas.

▪ Commercial and Residential Furniture

In addition to countertops, solid surface can also be used in commercial and residential furniture. Its seamless appearance allows for sleek designs that are both functional and aesthetically pleasing. Whether it's a desk, table, or shelving unit, solid surface can add a touch of modernity to any space.

▪ Wall Cladding and Paneling

Another popular application for solid surface is wall cladding and paneling. With its ability to be molded into various shapes and sizes, it can create unique textures and patterns on walls that enhance the overall design of a room.

▪ Healthcare and Laboratory Surfaces

Solid surface materials are also commonly used in healthcare settings such as hospitals and laboratories. Their hygienic properties make them easy to clean, reducing the risk of contamination in sensitive environments.

▪ Retail and Hospitality Spaces

The retail industry has also embraced the use of solid surface materials in store fixtures such as display cases or point-of-sale counters. The seamless integration of these surfaces adds an element of sophistication to any retail space. The applications for solid surface materials are vast and varied. From kitchens to healthcare facilities to retail spaces, the versatility and durability make it a popular choice among designers and architects alike.

Choosing the right solid surface for your project can be a daunting task. With so many options available in the market, it's important to consider various factors before making a decision.

- Think about the purpose of your project. Is it for a kitchen countertop, bathroom vanity, or commercial space? Different solid surfaces have different strengths and weaknesses, so choose one that suits your specific needs.

- Next, consider the aesthetics. Solid surfaces come in a wide range of colors and patterns to match any design style. Whether you prefer a classic marble look or a modern concrete finish, there is something for everyone.

- Durability is another crucial factor to consider. Look for solid surfaces that are resistant to scratches, stains, and heat. This will ensure that your investment lasts long without requiring frequent repairs or replacements.

- Additionally, take into account maintenance requirements. Some solid surfaces require regular sealing while others are low-maintenance and easy to clean with just soap and water. Choose one that fits well with your lifestyle and time constraints.

- Don't forget about budget considerations. Solid surfaces vary in price depending on their quality and brand reputation. Set a realistic budget and find options within that range without compromising on quality.

By considering these factors - purpose, aesthetics, durability, maintenance requirements, and budget - you can make an informed decision when choosing the right solid surface for your project.

Solid surface installation can be a straightforward process if you follow some key tips. First and foremost, it's important to ensure that the surface where the solid surface material will be installed is clean and free of any dust or debris. This will help to achieve a smooth and seamless finish.

1. Before starting the installation, make sure to measure and cut the solid surface material accurately. It's advisable to use a fine-toothed saw or router with a carbide blade for this purpose. Take your time during this step to avoid any mistakes;

2. Next, apply adhesive evenly on both the substrate (the underlying structure) and the backside of the solid surface material. Be careful not to use too much adhesive as it may cause excess seepage or create uneven surfaces;

3. Once you have applied the adhesive, carefully position the solid surface material onto the substrate. Apply even pressure across its entire length while ensuring proper alignment with adjacent pieces if applicable.

4. After positioning each piece in place, use clamps or weights to hold them firmly until they are fully bonded together. This will prevent any movement during curing;

5. Allow sufficient time for curing based on manufacturer recommendations before removing clamps or weights. Once cured, remove any excess adhesive using a scraper and sand down any rough edges if necessary.

By following these installation tips, you can achieve a professional-looking installation of solid surface materials in your project!

Taking proper care of your solid surface countertops or surfaces is essential to ensure their longevity and keep them looking as good as new. Fortunately, maintaining solid surface materials is relatively easy.

1. Regular cleaning with mild soap and water is usually sufficient for day-to-day maintenance. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. In case of stubborn stains, a non-abrasive cleaner specifically formulated for solid surfaces can be used;

2. To prevent permanent damage, it's important to avoid exposing the surface to extreme heat or placing hot objects directly on it. Always use trivets or hot pads under hot pans or dishes. Although solid surface materials are resistant to most household chemicals, it's still recommended to wipe up spills promptly and avoid contact with harsh chemicals such as paint removers or oven cleaners;

3. In terms of everyday care, wiping down the surface after each use will help maintain its appearance and prevent build-up of dirt or grime. Regularly applying a non-abrasive polish can also enhance the luster and shine of your solid surface countertop.

By following these simple care instructions, you can enjoy the beauty and functionality of your solid surface for years to come without worrying about extensive maintenance routines.

Conclusion

Solid surface is a versatile and durable material that offers numerous benefits for various applications. Whether you're designing a kitchen countertop, bathroom vanity, or commercial space, solid surface can meet your needs while adding an elegant touch to the overall design. KKR Solid Surface is a leading solid surface manufacturer&factory for over 19 years, providing customiaztion serface for solid surface sheets, solid surface countertops, etc. KKR has many successful projects globally. Following are some of the KKR Solid Surface Fabrication Projects for your reference: Qatar's Ras Abu Aboud World Cup Stadium and Precinct Project, Dubai W Hotel Translucent Solid Surface Counters, KKR Distinct Solid Surface Stone Side Table, India Cochin LULU MAL Dining Tables, US Miami Hard Rock Bar Counter and Worktops, Dubai uBank Reception Desk, Doha Health Center, DW Bracelet Solid Surface Display Tray. Welcome to contact us for further information.

Copyright © 2019 Huizhou KKR Stone Industry Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.