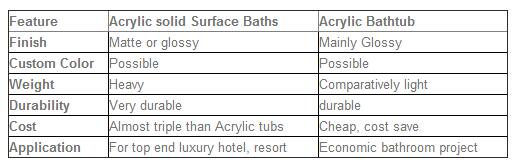

Some clients may misunderstand our acrylic solid surface bathtubs and confuse them with normal acrylic bathtubs. Then they raise the question of “why your acrylic baths so expensive, even up to triple the price of acrylic solid surface bathtubs?”

Actually, these two products are completely different. Hereby we list the differences of these two products to help you understand

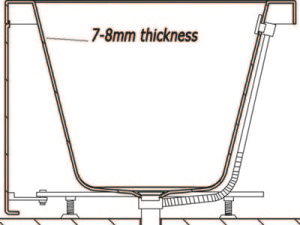

1. View of the structure

Normal acrylic tubs consist of several layers, the upper layer is 3-4mm of Polymeric Methyl Methacrylate(PMMA)which also called acrylic glass and is the face of acrylic tub. Under the face or skin of the tub is the reinforced fiber glass back bonded by polyester resin, which strengthens the structure and is usually 4-5mm thick. This is why some some people prefer to call an acrylic bathtub a “fiberglass bathtub”

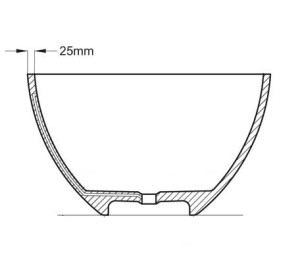

An acrylic solid surface (stone composite) bathtub no longer has such kind of layers. The product is solid throughout whole body, as its name ”solid surface” demonstrates., It is made with a kind of non porous composite stone material which was first introduced by Dupont in 1960s and proven and accepted by the market for more than 30 years.

Normally an acrylic solid surface bathtub’s body is approx 1.8-2.5cm thick and unlike a thin acrylic tub’s fragile structure, it’s very durable. If taken good care of, a fine quality solid surface acrylic bathtub can be used for several decades.

2.Base material difference

3.The acrylic tubs are made of 4mm PMMA slabs, strengthened by reinforced fiber glass.

Acrylic solid surface bathtub‘s base material are premium acrylic resin (compound of PMMA and MMA) and fine quality aluminum powder.

3. Different production method

To make an acrylic tub, one of the main methods is the plastic suction technique processing with acrylic slabs heated to 120-150 degrees centigrade. After cooling down, the required shape will be formed and then a reinforced fiber glass layer will be built to strengthen the shape.

Acrylic resin (MMA) is taken to produce a solid surface bathtub, where it is mixed with aluminum powder thoroughly in a cast machine. The mix is then placed into a vacuum, poured into a mold, and after cooling down the mold is opened and a primary acrylic solid surface bathtub is created.

4. Other prominent difference

We hope above the words can help you learn the differences between acrylic tubs and acrylic solid surface baths. Our products are only acrylic solid surface bath ware of the greatest quality.

Copyright © 2019 Huizhou KKR Stone Industry Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.